Proszę czekać...

Trwa wysyłanie formularza...

Trwa wysyłanie formularza...

Contact us

The principal material of the Woodcore-structure. Our technology uses KVH and BSH wood imported from a leading Austrian manufacturer.

KVH construction solid wood has German Quality Certificate (Zertifikat KVH MPA Stuttgart).

The certification description classifies it as a material used in state-of-the-art construction industry.

Technical properties:

C24 strength grade in accordance with the PN-EN 338:2016 standard

execution in accordance with the PN-EN 14080:2013, PN-EN 15497:2014, PN-EN 336:2013-12 standards

planed wood, beveled on four sides

kiln dried to obtain humidity 15 % +/- 3%

NRO-grade wall partition

D, s2, d0 (PN-EN 14080:2013) fire resistance

lack of fungi and insects

tree core splitting cut

no impairments or damages

repetitive shape and dimensions

Thanks to exclusive use of certified materials in the production process we are able to provide the highest quality of the building as well as guarantee stability and safety for long years ahead.

We use KVH and BSH wood (coming from Austria - dead and kiln dried wood)

The elements of the construction are joined with certified connectors only.

We use certified construction reinforcements (elements joined in one line)

In order to guarantee long-term stability of the construction we use carpenter connectors, anchors, screws and staples and other screw connectors provided by well-known, world leading manufacturers.

Thanks to the use of certified connecting materials and tools we are able provide the highest quality and stability of construction and thus the safety of the inhabitants.

Each and every element of the building (wood, screws, steel connectors) is certified for quality in order to make sure that the products offered by us fulfill all safety standards.

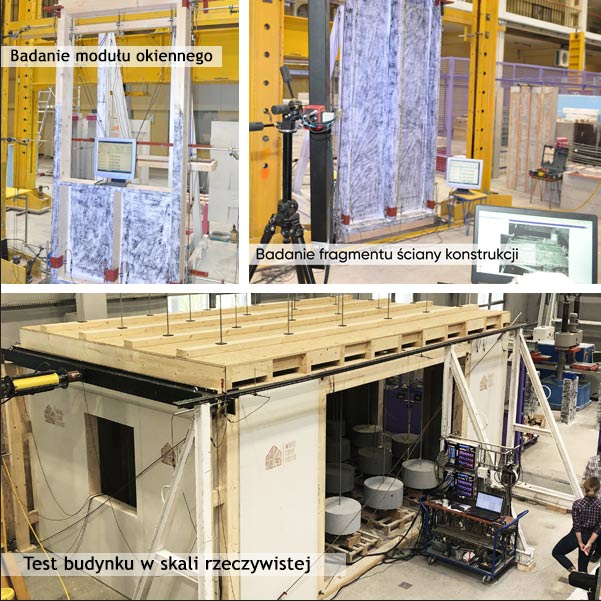

In Woodcore we always strive to meet customer’s expectations and support our promises with honest research and test. We are one of the few companies that carry out strength tests in real-life scale.

In cooperation with the Silesian University of Technology we test both single elements, fragments of walls, walls with ceiling as well as the whole structures. Up to now we have already carried out more than a dozen tests on full-sized elements and the results show that our structures fulfill, with a large margin, the required strength standards.

Thanks to National Centre for Research and Development we have equipped a production line, thanks to which we will soon be able to produce our core buildings.

As a result of our proprietary solutions 80% of the ordered building shall always be available in the workshop, we will be able to manufacture the remaining part within 3 days.

After delivery of the Wood Pack, this is what we call our different types of buildings, together with instruction manual, 2 to 4 persons’ team shall have no problems whatsoever to assemble the building shell from the elements in merely 6 days.

The speed of assembly will substantially exceed that of traditional core construction and the obtained rigidity will be substantially higher than that of the present wood construction available on the market.

We may say that the construction of a Woodcore building will be as easy as Lego bricks assembly.

Obviously, the assembly time will depend on the size of the structure its degree of complexity and the quantity of workers available on the construction site. We are developing a simple and intuitive assembly manual for our Wood Packs. We assume that 2, 3 or 4-person construction team shall be sufficient to erect a building within approximately 6 working days.

Oferujemy kompletną, gotową do montażu konstrukcję budynku szkieletowego składająca się z modułów (konstrukcja drewniana z zewnętrznym poszyciem) wraz ze wszystkimi niezbędnymi elementami złącznymi, jak: śruby, kotwy, łączniki (dostarczamy wyłącznie certyfikowane elementy). Konstrukcje mogą być poszyte płytą fermacell o zwiększonej odporności na ogień lub płytą OSB3 o zwiększonej odporności na wilgoć i wolną od związków formaldehydu.

Stosujemy zwiększone przekroje elementów składowych szkieletu tj. przekrój słupów konstrukcji wynosi 8 x 16 cm, w narożach dodatkowo masywne słupy, konstrukcja stropu z belek o przekrojach 8 x 24 cm lub 8 x 30 cm.

Rozwiązanie to gwarantuje wytrzymałość i stabilność budynku, co zostało potwierdzone wieloma badaniami nośności, sztywności i odkształcalności na obciążenia grawitacyjne (pionowe) pojedynczych elementów oraz fragmentów i całej konstrukcji.

Wypełnienie konstrukcji (Standard energetyczny budynku):

Nasz system nie wyklucza żadnego rodzaju ocieplenia, przez co można zastosować rozwiązanie adekwatne do potrzeb klienta. Może to być wełna mineralna, celuloza, piana wysokorozprężna otwarto- lub zamkniętokomórkowa, wełna owcza, itp.

Contact us

Are you interested in the most cutting-edge technology of building wood-core houses?

Are you an architect, contractor or construction company? We are looking for partner companies interested in designing and building core-structure houses. Write to us or call us in order to find out more about our own original technology.

A proprietary modular timber frame system using prefabricated elements made of wood, wood-based and composite materials. Lightweight, durable and quick to assemble – designed for modern, sustainable construction.

Lightweight, durable and quick to assemble – designed for modern, sustainable construction.